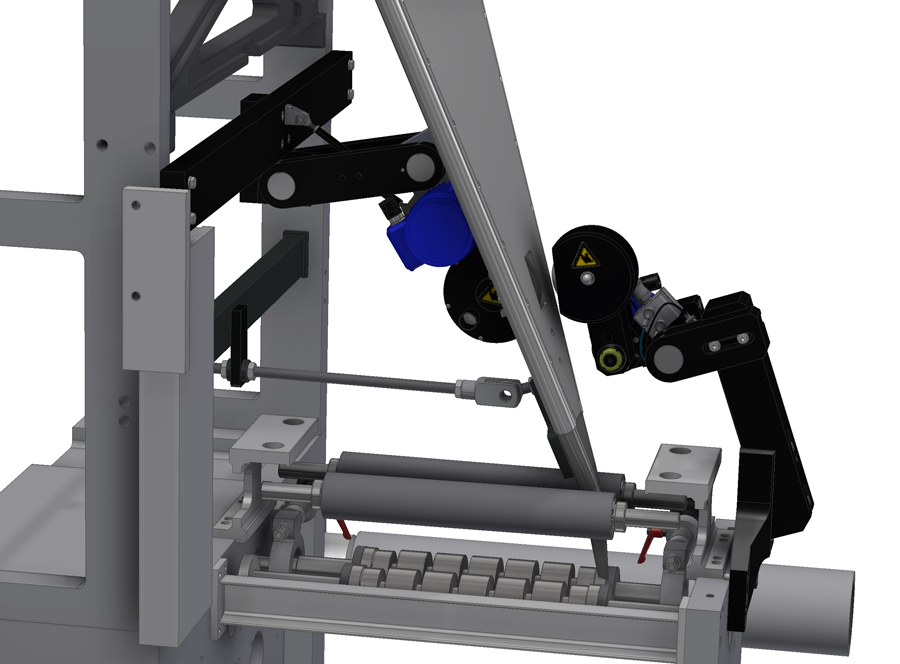

Double Motorised Tab Slitter

OFFSET SLITTERS (1st FOLD)

For scissor-like clean cuts of highly-paginated printed products.

Many newspapers have embraced the benefits associated with switching to a stitchable compact format – not least because of its proven reader satisfaction. The Tolerans Double Motorized Tab Slitter, based on unique technology, was developed to make clean, dustless, aesthetic cuts in highly-paginated printed products to achieve these formats. When combined with stitching, the result is a newspaper with a more accessible ‘magazine feel’.

Product Description

Tolerans Double Motorized Tab Slitter is a revolutionary technological advance. Thanks to the spring-loaded contact point between its knives, the tab knife produces a high-quality scissor-like cut that is almost dustless compared to conventional crush web slitting on an RTF roller, even in the case of highly-paginated printed products. Both the upper and lower knife are actively driven, which dramatically increases the maximum number of webs that can be cut without compromising high cutting quality.

Features

- Clean cuts.

The Tolerans Double Motorized Tab Slitter produces a much cleaner, more aesthetic cut than other tab slitters on the market, thanks to the spring loaded contact point between the knives. This ensures scissor-like performance every time. - Less dust.

Because fibres are cut cleanly instead of crushing them, the paper produces much less dust during the cut. - High capacity cuts.

By actively driving both the upper and the lower knife, even products with high pagination can be slit without having to compromise on the quality of the cut. - Minimized risk of web rupture.

The knives are driven at a peripheral speed that is 10 per cent higher than the web speed. This prevents the web from tangling on the knife, since it always pulls away from the web, thus minimizing the risk of web rupture. - Better web tension control.

By cutting through a hole in the former closer to the nose, the web is kept intact longer than with conventional slitting in the RTF roller. This gives the printer better control over web tension.

Specifications

- Clean cuts at web speeds up to 10.5 m/s.

- Cuts up to 12 webs on 55 gsm paper.

Requirements

- Requires air supply of minimum 6 bar.

- Power supply: 1 phase 230 V, 10 A.

- Requires adequate space around the former.

Service & Maintenance

Full documentation and customized manuals for the stitching solutions are always provided.

To enjoy ideal performance and reliable production in any stitching system, wear parts must be replaced regularly. All systems are equipped with a customized Wear and Spare Part Program that makes it easier to know when, how and what to replace. The different wear part kits are designed to be replaced at certain interval points. The wear part kits enable quicker replacements with less downtime and, where applicable, all mechanical settings are pre-set when delivered.