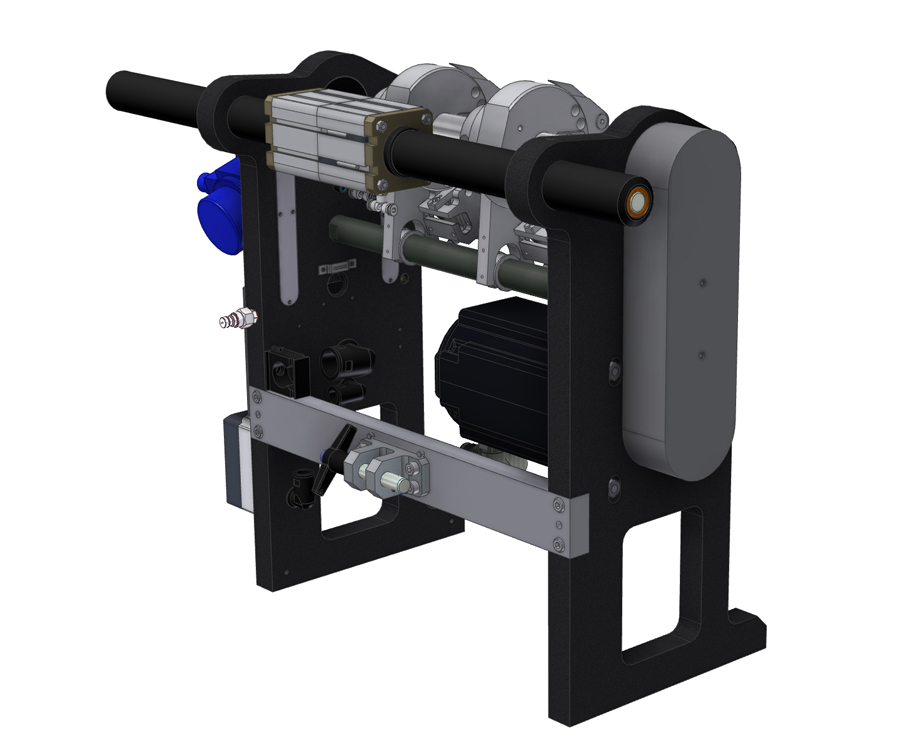

SPEEDLINER® 2.0 Digital Cylinder

DIGITAL CROSS - CYLINDER

A reliable, high-speed, shaftless, modular stitching systems for the flexible production of digitally printed newspaper and commercial print.

The SPEEDLINER® 2.0 Digital Cylinder uses well proven technology and is suitable for the new digital printing presses in the next-generation stitching systems for newspapers and commercial print. This stitching application allows stitching in-line at full production speeds and contributes to a higher quality end product. A high-end, reliable solution thanks to its flexible, modular design.

Product Description

The SPEEDLINER® 2.0 Digital Cylinder is suitable for the new digital printing presses and perfect for stitching newspapers and commercial printed products. Fully shaftless and servo driven, it stitches against the folding cylinder. The press collects variable number of digitally printed pages on a collect cylinder before transferring them to the folding cylinder. A signal from the press control (or a print mark) informs the stitching system when to staple the product. This front-line stitching system makes greater production flexibility and cost effective, high-performance in-line stitching possible. The SPEEDLINER® 2.0 Digital Cylinder is modular, durable, reliable and easy to install, maintain and operate. This ensures a completely worry-free stitching process.

Features

- For cross-web stitching of compact size printed products.

For any web width.

- Stitches at full production speed.

- Moves on rails for easy handling.

SPEEDLINER® 2.0 Digital Cylinder moves on rails to allow better access to the folding cylinder parts, making the replacement of consumables and parts easy.

- Modular construction for easy maintenance.

The SPEEDLINER® 2.0 Digital Cylinder is easy to operate and to maintain, minimizing downtime. The central lubricating system lubricates the cam and major bearings. The stitcher features a service cassette that includes the stitching fork, the wire rest and an easily removable cutting/forming unit. The modular design allows users to change wear parts without having to make any adjustments.

- Customized, modular control system for easy operations.

The stitching system includes a customized, modular control system based entirely on standard components, where the functions are remote-controlled for easy operations.

- Includes high-end standard features.

Standard features include servo drives (both on main and wire feed motor), controller, touch screen operator terminal and remote connection via modem or Ethernet.

Specifications

- Stitches at full production speed.

- Staple width: 14 or 16 mm.

- Wire gauge: 0.5 or 0.6 mm diameter.

- Cut-off length: Adapted to collect cylinder.

- Weight: 100-150 kilos.

- Two axis servo technology.

- Wire feed with intermittent feeding.

- Able to run with traditional unwinders or Tolerans DrumTop.

- Automatically controlled pagination adjustment.

Requirements

- Power supply: 3×380-480 V AC, 20 A.

- Requires air supply of minimum 6 bar.

Service & Maintenance

Full documentation and customized manuals for specific stitching solutions are always provided.

To enjoy ideal performance and reliable production in any stitching system, wear parts must be replaced regularly. All systems are equipped with a customized Wear and Spare Part Program that makes it easier to know when, how and what to replace. The different wear part kits are designed to be replaced at certain interval points. The wear part kits enable quicker replacements with less downtime and, where applicable, all mechanical settings are pre-set when delivered.

Video